China's Intelligent Manufacturing Illuminates Africa: Xingke Group Undertakes 20,000 Utility Pole Projects in Africa in 2024

Mar.03.2025

(Xingke Group Headquarters, March 15, 2024) Amid the dual trends of global energy transition and infrastructure upgrades in Africa, China's Xingke Group has officially announced strategic cooperation with multiple African governments and international organizations to complete the production, transportation, and installation of 20,000 new utility poles in Africa within 2024. This project marks a milestone for Chinese manufacturing in serving Africa's energy interconnection and is a vivid example of high-quality co-construction of the Belt and Road Initiative between China and Africa.

Breaking "Electricity Islands": Chinese Solutions Boost Africa's Energy Arteries

The African continent has long faced challenges of insufficient electricity coverage and aging transmission infrastructure. According to the World Bank, over 600 million people in sub-Saharan Africa still lack stable access to electricity, with some countries having a power grid coverage rate of less than 30%. Utility poles, as the "skeleton" of power transmission, directly affect the efficiency of the power grid and the development of livelihoods.

The 20,000 utility pole order undertaken by Xingke Group will cover 12 countries, including Kenya, Nigeria, and Tanzania, and will be mainly used for urban power grid expansion, rural electrification, and cross-border high-voltage transmission projects. Upon completion, the project is expected to add 4,000 kilometers of new transmission networks, benefiting over 3 million households and reducing annual carbon emissions from traditional diesel generators by approximately 150,000 tons.

Empowering with Technology: From "Made in China" to "Made in Africa"

To adapt to Africa's complex geography and climate, Xingke Group has innovatively developed the "Tropical Smart Utility Pole"—made from high-strength composite materials and corrosion-resistant coatings, capable of withstanding temperatures up to 50°C, acidic soils, and salt fog erosion. The poles are equipped with IoT sensors for real-time monitoring of line load, temperature, and fault locations, enhancing the efficiency of power grid maintenance.

"We are not only exporting products but also focusing on technology transfer," said Li Ming, President of Xingke Group's Africa Division, at the signing ceremony. The project plans to establish two localized production bases in Nigeria and South Africa and train 500 local power engineers in collaboration with local universities to upgrade Africa's indigenous industrial chain. "In the future, utility poles made in Africa will bear the label of 'China-Africa Cooperation' and enter the global market."

Green and Win-Win: ESG Philosophy Throughout the Entire Chain

The project's environmental attributes and community participation are highlights. The utility pole production uses photovoltaic-powered recycling workshops, saving 30% energy compared to traditional processes, and discarded poles can be 100% recycled and reshaped. Additionally, the group has committed to building a solar-powered classroom for local communities for every 100 utility poles installed, promoting educational equity.

Conclusion: Weaving a Bond of Light

From villages on the edge of the Sahara Desert to industrial corridors along the East African Rift, the 20,000 utility poles will stand tall, supporting an intricate network of silver lines and transmitting the pulse of electricity to every corner of the African continent. Jin Baotai, Chairman of Xingke Group, said, "We look forward to working with African partners to draw a blueprint for energy interconnection, making every lit lamp a warm footnote to the China-Africa community of shared future."

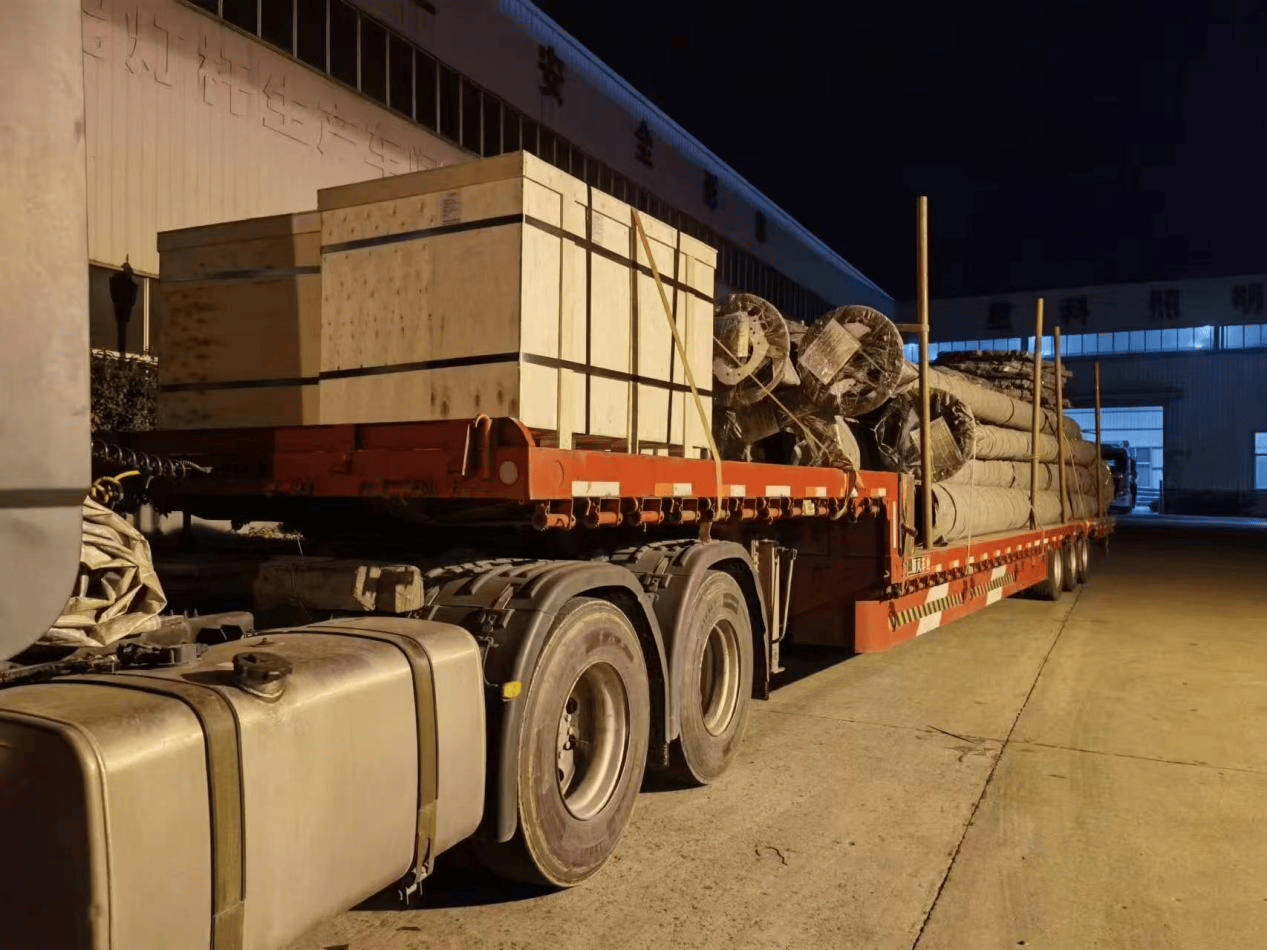

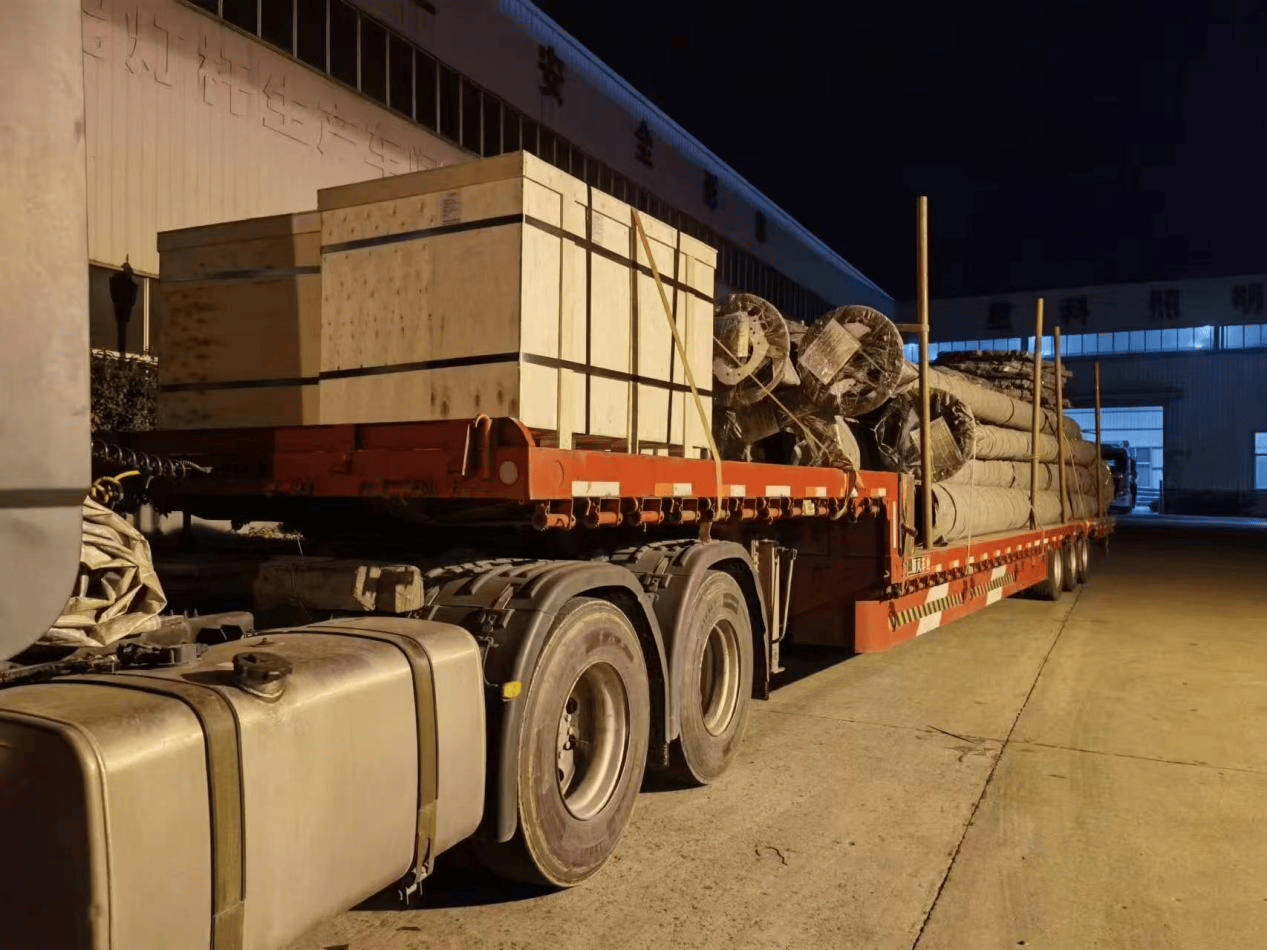

It is reported that the first batch of 5,000 utility poles set sail from Shanghai Port, China, in the first quarter of 2024. This "journey of light" across the Indian Ocean is slowly unfolding.

Background: Xingke Group has been deeply involved in the power infrastructure sector for 16 years, with operations in over 60 countries worldwide. Its independently developed sixth-generation composite utility poles have received certification from the International Electrotechnical Commission (IEC) and lead industry standards in key indicators such as wind resistance and corrosion prevention.